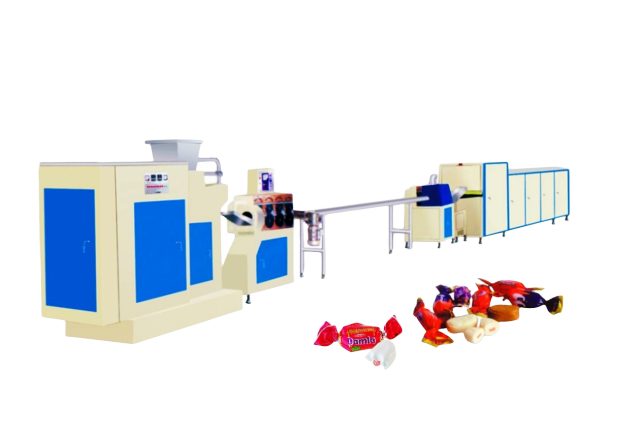

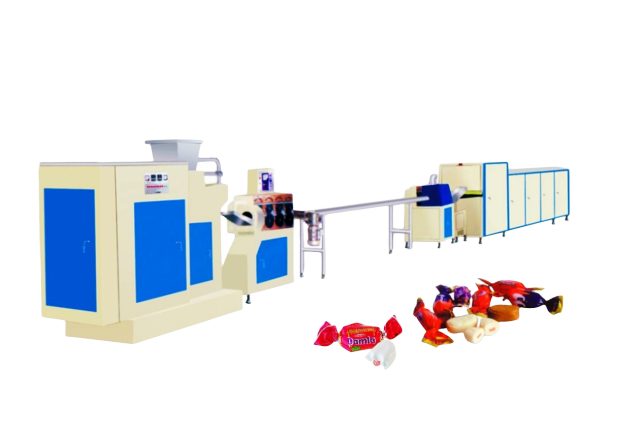

Introduction To Milk Candy Production Line:

The milk candy production line is developed according to the change in candy production and consumption markets in recent years. With the increase of people's living conditions, the needs for candy tastes are developing towards low sugar, multiple styles, nutrition and health care. The central filled milk candy production equipment is developed by our company on the basis of introducing advanced technology. The production line is mainly composed of jam conveying pump, candy extruding and forming machine, sizer, chain type forming machine, oscillating distributor, cooling and conveying table, refrigerator, etc. It can produce soft filled milk candies and filled toffees such as Eclairs.

Milk Candy Production Line Components:

01.Steam Sugar Melting Pot

02.Gear Pump

03.Syrup Storage Tank

04.Rotor Pump

05.Milk Candy Cooker

06.Cooling Table

07.Center Filling Machine

08.Extruding Machine

09.Rope Sizer

10.Cooling Conveyor

11.Chain Type Forming Machine

12.Swing Distributing Machine

13.Cooling Tunnel

14.Double Twist Packing Machine

Technical Parameters Of Milk Toffee Candy Production Line:

|

Machine Model |

PD300/PD500 |

|

|

Output Capacity |

300KG/H-500KG/H |

|

|

Forming Speed |

1000-2000Pcs/Minute |

|

|

Candy Weight |

Outside Shell 7Grams; Inside Filling 2Grams |

|

|

Candy Shape |

Customized |

|

|

Main Material |

SUS304 |

|

|

Heating Source |

Electricity or Steam Heating |

|

|

Steam Consumption |

600KG/H-1000KG/H |

|

|

Steam Pressure |

0.2MPa-0.8MPa |

|

|

Installed Power |

Electric Heating |

80/150KW |

|

Steam Heating |

50/80/KW |

|

|

Power Supply |

380V/220V/50Hz/60Hz/3PH |

|

|

Area Covered |

25-30*5-8*3M |

|