Introduction To Full Automatic Chocolate Production Line:

Full Automatic Chocolate Production Line Components:

01. Sugar Grinder

02.Fat Melting Tank

03.Delivery Pump

04.Chocolate Conch

05.Delivery Pump

06.Ball Miller

07.Delivery Pump

08.Warm Holding Tank

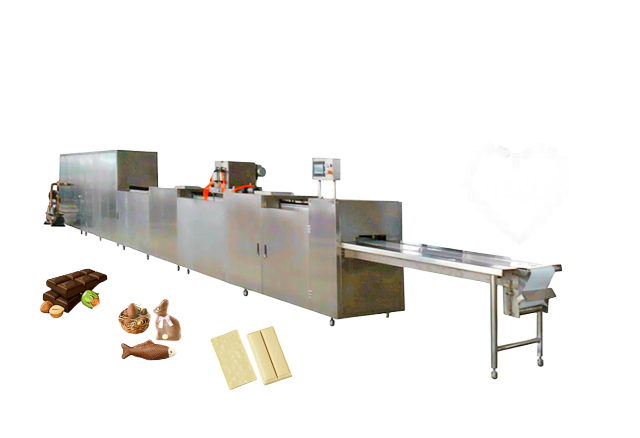

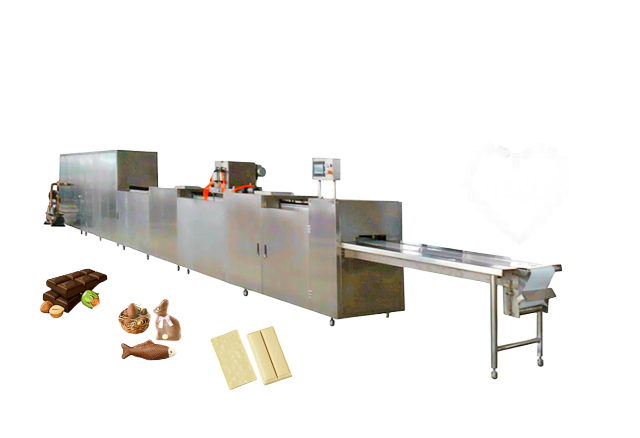

09.Tempering Machine

10. Chocolate Depositing-Forming-Vibration- Cooling-Demoulding-Moulds Heating-Conveying System

| Items | PD150Single Shot | PD300Double Shots | PD500Triple Shots | |

| Production Capacity | 150-200KG/H | 250-300KG/H | 450-500KG/H | |

| Depositing Speed | 8-15Moulds/min | 8-15Moulds/min | 8-15Moulds/Min | |

| Chocolate Weight | Pure Chocolate | 0-600Grams | 0-600Grams | 0-600Grams |

| Filled Chocolate | 15%-30% | 15%-30% | ≥50% | |

| Cooling Temperature | 5-10℃ | 5-10℃ | 5-10℃ | |

| Environment Temperature | 22~25℃ | 22~25℃ | 22~25℃ | |

| Cooling Power | 15 HP Water cooled refrigerator | 15 HP Water cooled refrigerator | 20 HP Water cooled refrigerator | |

| Cooling Ways | It adopts centrifuge for closed and circulated cooling | |||

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | |

| Total Power | 28KW | 32.5KW | 43KW | |

| Mold Quantity | 220Pcs/Set | 350Pcs/Set | 450Pcs/Set | |

| Gross Weight | 8500KG | 11500KG | 15000KG | |

| Outline Dimensions | 16000×1500×2000MM | 19000×1100×1800MM | 45000×1200×2200MM | |