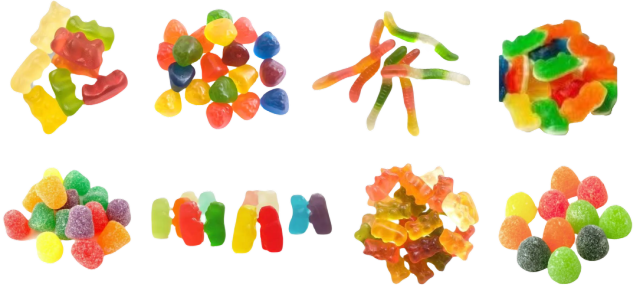

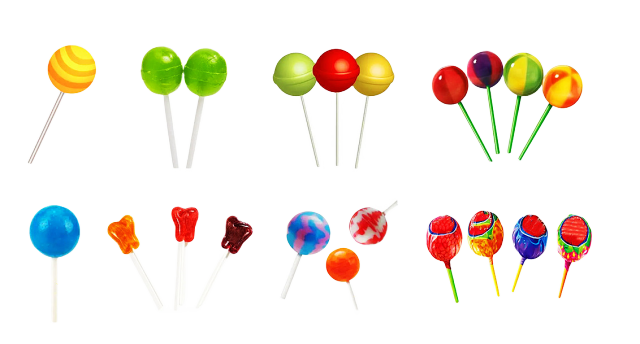

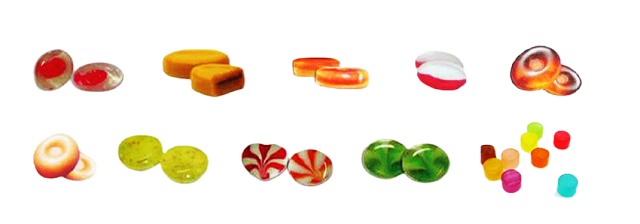

Introduction To The Three-In-One Gummy Candy Hard Candy And Lollipop Production Line:

Three In One Gummy Candy Hard Candy and Lollipop Production Line Components:

01 Automatic Weighing and Mixing System|

Machine Model |

PD80/150/300/450/600KG/H |

|

|

Output Capacity |

80/150/300/450/600KG/H |

|

|

Depositing Speed |

45-50Drops/Minute |

|

|

Stick Plug Speed |

20-25Times/Minute |

|

|

Candy Weight |

8-25Grams/Pcs |

|

|

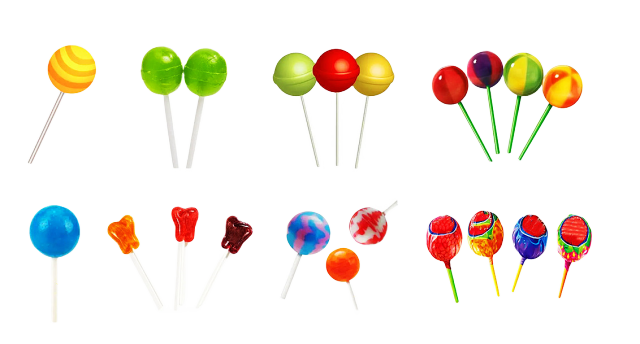

Candy Shape |

Customized |

|

|

Main Material |

SUS304 |

|

|

Compressed Air Consumption |

0.3/0.6/0.9/1.2/1.5CBM/Hour |

|

|

Compressed Air Pressure |

0.2-0.6MPa |

|

|

Heating Source |

Electricity or Steam Heating |

|

|

Installed Power |

Electric Heating |

80/110/120/150/180KW |

|

Steam Heating |

40/60/70/90/120KW |

|

|

Power Supply |

380V/220V/50Hz/60Hz/3PH |

|

|

Area Covered |

25-35*6-10*4M |

|