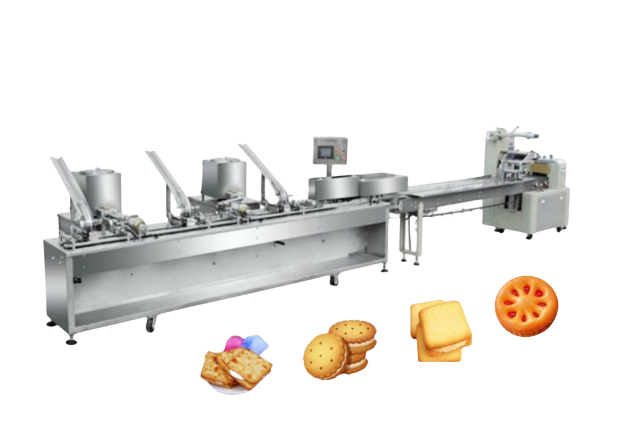

Introduction Of Soft and Hard Biscuit Production Line:

Soft and Hard Biscuit Production Line Components:

01.Automatic Flour Mixer

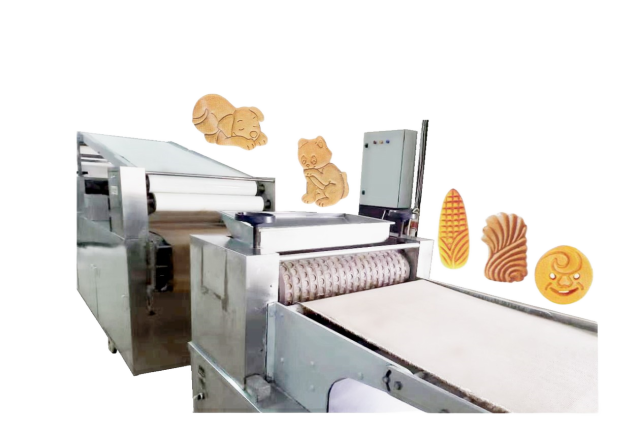

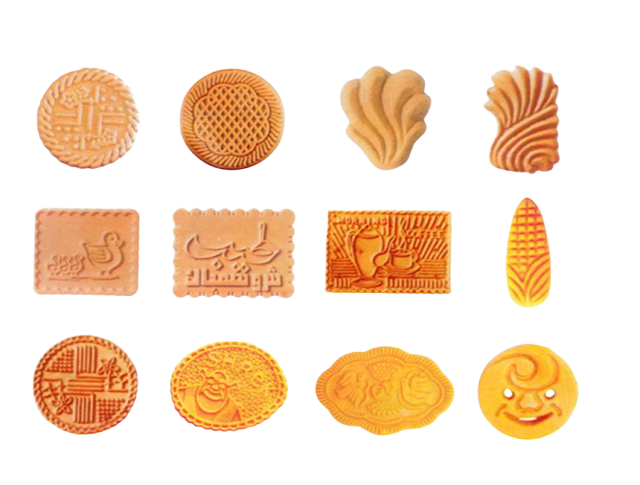

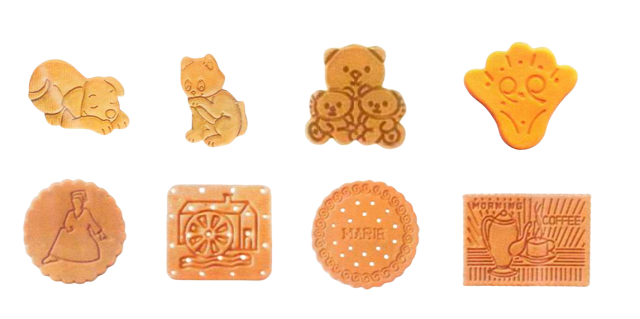

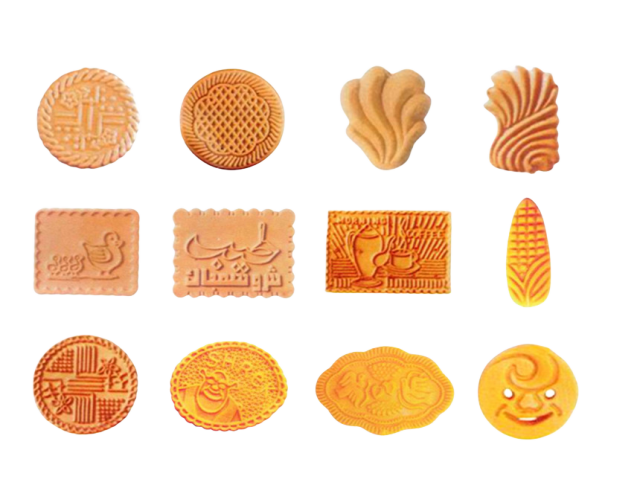

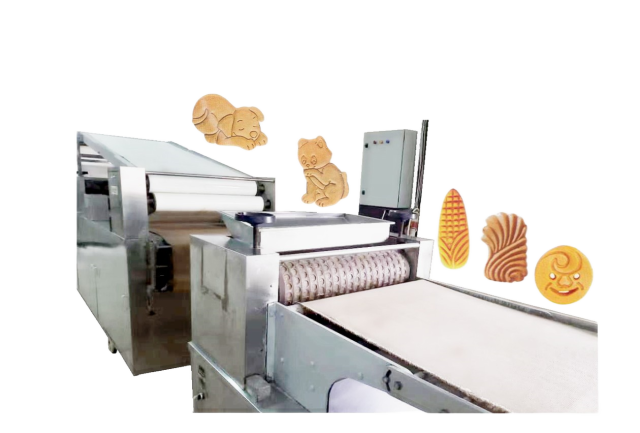

02. Dough Cutter With Conveyor

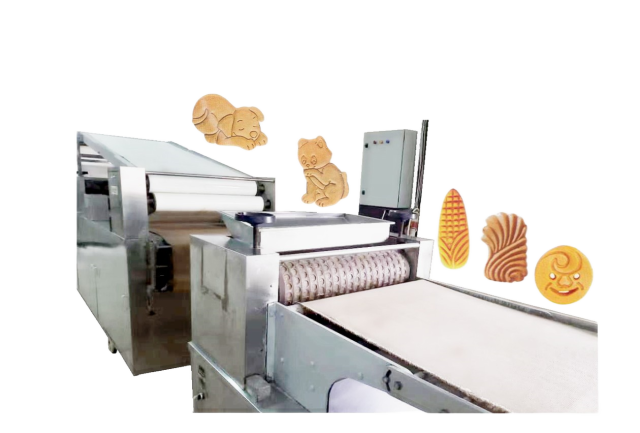

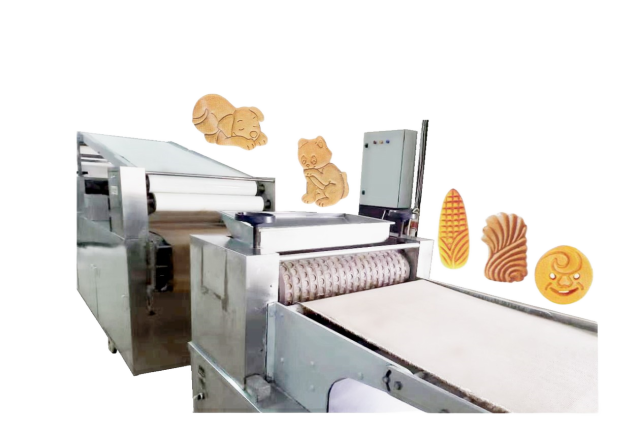

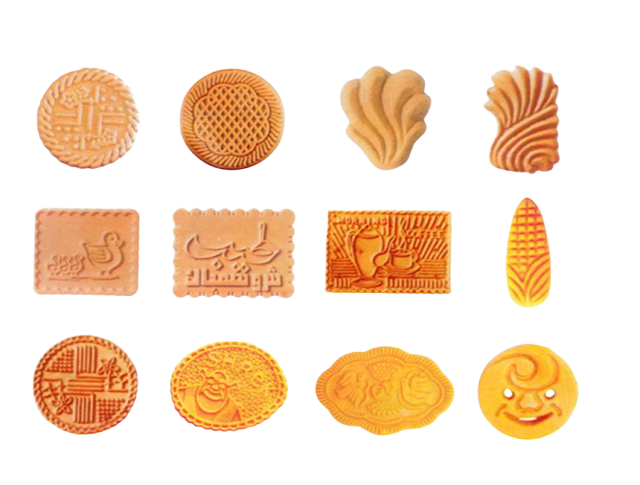

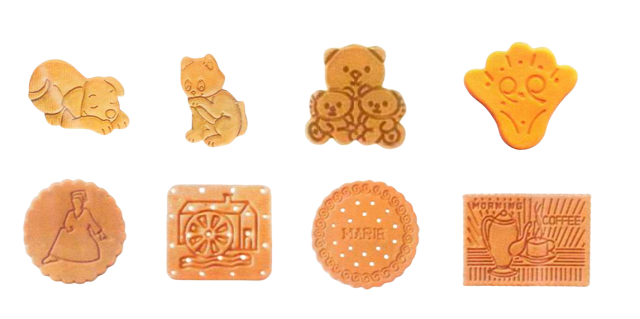

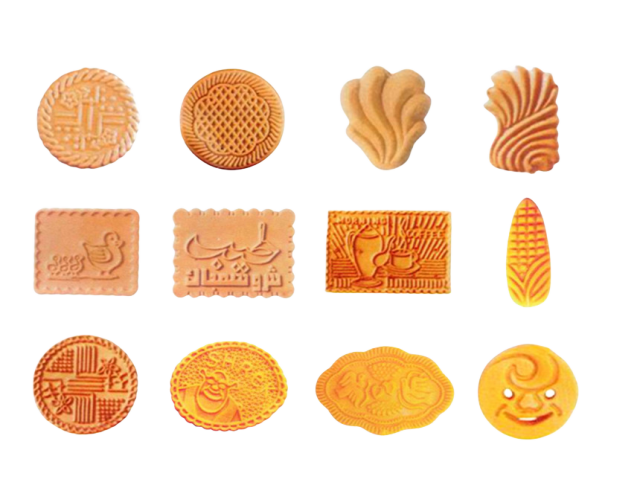

03.Hard Biscuit Forming Machine

04.Soft Biscuit Forming Machine

05.Entering Oven Machine

06.Tunnel Baking Oven

07.Out Oven Machine

08.Peeling Machine

09.Oil Sprayer

10.Oil Filter

11.SwervingMachine

12.Cooling Conveyor

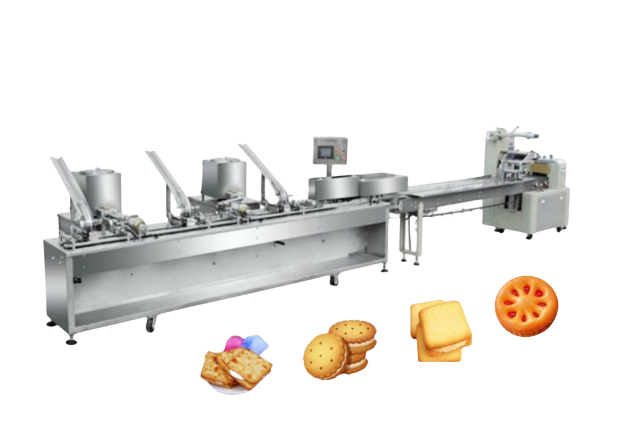

13.Track Stacking Machine

14.Packing Table

15.Biscuit On Edge Packing Machine

Technical Parameters of Soft and Hard Biscuit Production Line:

| Items | PD250 | PD300 | PD400 | PD480 | PD600 | PD800 | PD1000 | PD1200 | PD1400 | |

| Production Capacity | 80KG/H | 150KG/H | 200KG/H | 280KG/H | 480KG/H | 800KG/H | 1200KG/H | 1400KG/H | 2000KG/H | |

| Biscuit Weight | 5-20Grams | 5-20Grams | 5-20Grams | 5-20Grams | 5-20Grams | 5-20Grams | 5-20Grams | 5-20Grams | 5-20Grams | |

| Baking Temperature | 150-180℃ | 150-180℃ | 150-180℃ | 180-250℃ | 180-250℃ | 180-250℃ | 180-280℃ | 180-280℃ | 180-280℃ | |

| Tunnel Oven Length | 20M | 30M | 30M | 30M | 40M | 60M | 60M | 60M | 75M | |

| Temperature Zone | 3Zones | 3Zones | 3Zones | 3Zones | 4Zones | 4Zones | 4Zones | 5Zones | 5Zones | |

| Power Source | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | |

| Electric Oven Power | 80KW | 150KW | 180KW | 210KW | 280KW | 500KW | 800KW | 1000KW | 1500KW | |

| Gas Consumption | / | / | / | 30CBM/H | 40CBM/H | 75CBM/H | 120CBM/H | 150CBM/H | 220CBM/H | |

| Diesel Consumption | / | / | / | 31L/H | 42L/H | 85L/H | 136L/H | 170L/H | 250L/H | |

| Workshop Size | 33*5*3M | 43*6*3M | 45*6*3M | 45*6*3M | 55*6*3M | 80*10*3M | 85*15*3M | 90*20*3M | 110*20*3M | |